This section describes the laser welding equipment for the ccs acquisition board of the battery module

Date:2024-01-15 Source: This website

With the vigorous development of the new energy automobile industry, the accessories products around the new energy automobile industry are also developing rapidly, including new energy batteries as the core components, its process and technology are also rapidly upgrading, and laser is an essential tool for new energy batteries, for this reason, Jinghai laser for new energy vehicles, new energy batteries, Energy storage battery and hydrogen fuel cell industry has developed a series of laser special equipment, the following we focus on the battery module ccs acquisition board laser welding automatic production line:

The picture is for reference only, according to the specific product design

First, equipment process analysis:

1. FPC feeding station: manual feeding, different products with different fixtures, can be quickly switched

2. Laser welding station: double gantry structure, double up and down stations, equipped with laser altimeter system and high precision vision software, accurate welding without deviation, high efficiency, good quality;

3. Welding inspection station: high-pixel camera is used to take photos of the welding joints, mainly to detect the welding position, size and appearance of the welding joints, to ensure the welding quality

4. Voltage drop test station: mainly electrical performance test link, test voltage resistance and insulation performance to ensure the electrical performance of the product

5. NTC test station: on-off test of nickel sheet welding position, FPC wiring harness and NTC to detect welding quality

6. Receiving station: the bad ones are disposed of directly after detection, and the qualified ones receive the tray, mainly by manual sorting

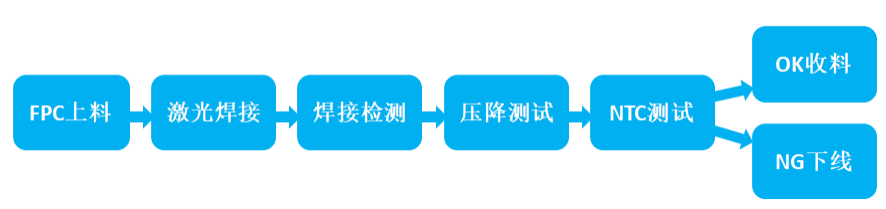

Process flow chart

Second, equipment features:

1. The automatic production line has a high degree of automation, the equipment fixture has a quick change function, you can replace different product fixtures according to need, just manually replace the fixture and switch the software;

2. The production line is stable, reliable, high quality and efficient, which can greatly improve the production capacity and efficiency of the enterprise

3. The production line is equipped with MES system, so that all the data of the production process can be visible, digital production can be realized, and the factory management level is better

4. The production line combines man and machine, the function is flexible, and the labor cost can be greatly reduced

5. The production line makes laser welding and product inspection perfectly compatible, the process is smooth, seamless, efficient and intelligent

6. The production line is arranged in a row, which can save the floor area and efficiently use the space

7. All data is automatically generated and judged, the data is formed into a report, the data corresponds to the two-dimensional code one by one, the data is saved locally, and the deadline is controlled by itself;

8. All products with FPC can be compatible to the maximum product size 2000*800mm;

Suzhou Jinghai Laser is dedicated to the new energy battery industry, this automated production line is specially developed for the battery module ccs acquisition board, intelligent and efficient, welcome to call us!

Related news

- Introduction and application of laser tin wire welding

- Application and classification of laser soldering

- Jinghai laser large field laser welding machine helps battery module CCS module welding

- CO2 laser cutting machine dimming steps

- The difference between various kinds of laser welding machine

- Laser welding of medical endoscopes

- Application of picosecond laser cutting machine in glass industry

- The difference between coaxial vision, pseudo-coaxial vision and paraxial vision

- Introduction to precision ceramic laser processing equipment

- Introduction of standard automation equipment for large format glass laser cutting

Building 4, 88 Wubian Avenue, Wujiang District, Suzhou

Building 4, 88 Wubian Avenue, Wujiang District, Suzhou