Application of picosecond laser cutting machine in glass industry

Date:2024-01-15 Source: This website

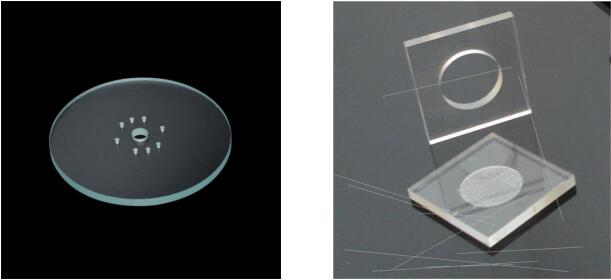

Since the glass material, due to its particularity, it is not only used in life as a decorative material, but also widely used in the industrial field, and its figure is everywhere. Laser as an important processing tool for glass products, but also rapid development, the following focuses on the application of picosecond laser cutting machine in the glass industry.

The picosecond laser is a laser with a pulse width of picosecond. It has the characteristics of picosecond ultra-short pulse width, adjustable repetition frequency and high pulse energy. Due to low thermal energy diffusion, the material has been interrupted before the heat has been transmitted to the material's periphery, so it has no thermal effect on the material basically, and it can even be called cold processing.

Picosecond lasers also have many advantages over femtosecond lasers with shorter pulse widths, because there is no need to expand and compress the pulse for amplification, the design of picosecond lasers is less complicated, so More cost effective and reliable performance. At the same time, picosecond pulses are still short enough to handle very precise and stress-free micromachining.

1. The equipment adopts picosecond laser, the laser repetition rate is up to 1000 kHz, and the ultra-short pulse processing without complicated maintenance has no heat conduction;

2. Equipment operation without consumables, saving cost 0 vulnerable consumables, ultra-high stability;

3. The equipment adopts marble countertop, high stability;

4. High precision linear motor, fast response speed, high precision;

5. Equipped with CCD visual positioning, accurate positioning without deviation;

6. Can import graphics, achieve any path cutting, flexible processing;

7. The cutting format can be customized according to the product;

8. Picosecond laser cutting is mainly used in the processing of brittle materials such as sapphire, optical glass, semiconductor package chips, ultra-thin ultra-hard glass substrates.

Suzhou Jinghai laser research and development of picosecond laser cutting machine, once launched, ushered in a strong response in the market, praised by the majority of customers, Jinghai laser will, as always, strive to explore, with better quality, more professional service for the market, with professional quality and value in the laser industry market to establish a good brand image.

Related news

- Introduction and application of laser tin wire welding

- Application and classification of laser soldering

- Jinghai laser large field laser welding machine helps battery module CCS module welding

- CO2 laser cutting machine dimming steps

- The difference between various kinds of laser welding machine

- Laser welding of medical endoscopes

- Application of picosecond laser cutting machine in glass industry

- The difference between coaxial vision, pseudo-coaxial vision and paraxial vision

- Introduction to precision ceramic laser processing equipment

- Introduction of standard automation equipment for large format glass laser cutting

Building 4, 88 Wubian Avenue, Wujiang District, Suzhou

Building 4, 88 Wubian Avenue, Wujiang District, Suzhou