Patch resistance automatic laser soldering equipment

Price range: 600,000-800,000

Power: 200W

Warranty period: 2 years

Brand: Jinghai Laser

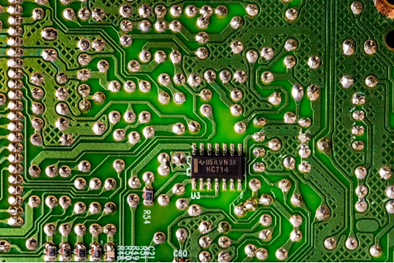

The automatic laser soldering system is a fully automatic customized assembly line. The IC components on PCB circuit board are welded by laser soldering. The system adopts a pipeline mode to transport the fixture, and the PCB is manually loaded onto the fixture. The fixture is transported to each automatic operating station through the assembly line, through the automatic spot flux, automatic IC, automatic welding, to complete the production of products.

Application description

C Automatic laser soldering system is a fully automatic customized assembly line. The IC components on PCB circuit board are welded by laser soldering.

The system adopts a pipeline mode to transport the fixture, and the PCB is manually loaded onto the fixture. The fixture is transported to each automatic operating station through the assembly line, through the automatic spot flux, automatic IC, automatic welding, to complete the production of products.

Laser application

The core process application of the equipment is mainly laser tin welding, and the traditional wave soldering and tin welding for some specific applications of the SMT industry can not meet the welding needs of the product, so the non-contact laser tin welding is used to weld the product, which has reached the final product process requirements.

Functional characteristics

The soldering of IC and PCB board is the most basic process of circuit board processing. This automatic solder technology solution, using mechanical hand material, laser solder method, provides a new solution for the whole processing process, and this solution can be compatible with a variety of different PCB and IC, breaking through the previous restrictions on IC, providing a new process and new ideas for the application industry.

Automatic production line, automatic production process, greatly improve the production efficiency, saving labor and cost.

Modular design, can be automatically adjusted through the program and structure, compatible with different PCB products welding. It can seamlessly and quickly switch between different products, with strong versatility and convenience.

Through the manipulator and CCD real-time monitoring for feeding, greatly improving the accuracy and speed of feeding.

Jinghai laser adopts high-quality flux valve body and temperature controlled laser, which can accurately meet the needs of PCB board and IC welding and meet the efficient needs of users.

System specification

The equipment consists of three parts: welding machine frame, workbench and welding machine. The table, the welding machine, the control panel, the start pause button is inserted in the welding machine body, the surface of the welding machine is provided with a microscope, a laser head, smoke purifier, etc., the left and right sides of the table are respectively provided with a fixed block, the inner wall of the fixed block is provided with a clamp block, the clamp block is closely fitted with the fixed block, the upper surface of the table is provided with a fixed table, The interior is provided with important components such as support columns.

Building 4, 88 Wubian Avenue, Wujiang District, Suzhou

Building 4, 88 Wubian Avenue, Wujiang District, Suzhou

Friendship link :