Inductor winding laser automatic equipment

Price range: 1.3-1.5 million

Power: 150W

Warranty period: 2 years

Brand: Jinghai Laser

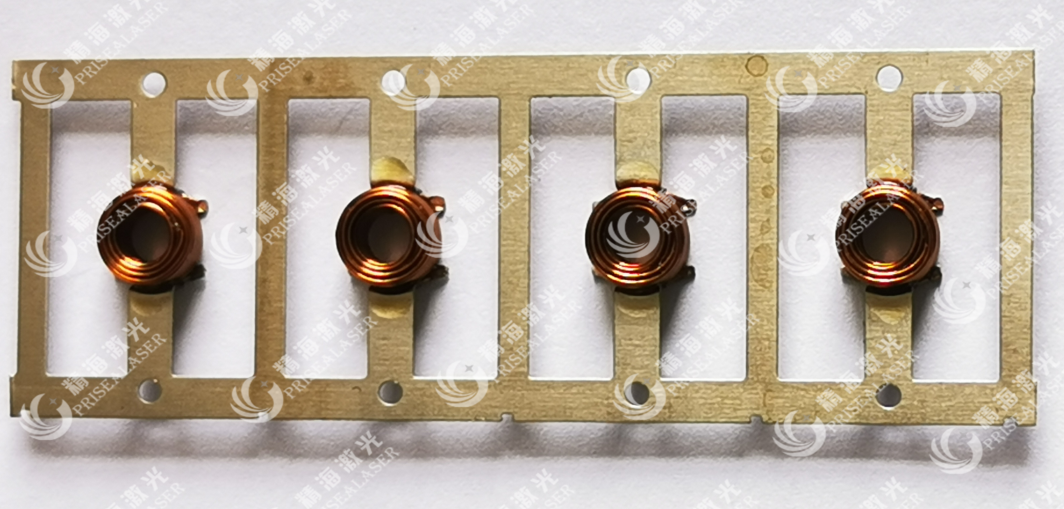

Automatic wire winding welding equipment, suitable for coil winding and welding of integrated inductors. The use of laser process to replace the original process, improve the production environment, improve production efficiency, and provide technical support for the development of smaller size inductors, from winding cutting, paint coating laser cleaning, coil and bracket precision spot welding to achieve automatic winding welding, high degree of equipment automation, product consistency...

Application description

Automatic wire winding welding equipment, suitable for coil winding and welding of integrated inductors. Using laser process to replace the original process, improve the production environment, improve production efficiency, and provide technical support for the development of smaller size inductors, from winding cutting, paint coating laser cleaning, coil and bracket precision spot welding to achieve coil automatic winding welding, high degree of equipment automation, product consistency, production yield and reliability.

Laser application

Inductor coil production has 6 to the process, through the laser process to replace the original process, laser cutting instead of the original knife cutting, laser cleaning instead of the original YAG box blasting mode, laser welding instead of resistance welding, making the production efficiency has 10 times the speed of improvement, and because of the advantages of laser process, so that the small size of the coil precision development is possible.

Functional characteristics

Compared with the traditional CNC winding and manual spot welding production process, it has the following significant characteristics:

1. The winding is directly wound on the precision mold, the coil position is accurate, there will be no deviation of the coil position after spot welding, and the multi-layer precision coil can be wound. There is no traditional winding wire clamping device may cause enameled wire clamping injury.

2.equipment operability, the automatic winding equipment to achieve a high degree of programmed control, simplify the traditional winding machine debugging process, low requirements for equipment operators. Ordinary inexperienced operators can start to operate within a week, different from the traditional winding machine requires many years of practical experience. The equipment can quickly change the line and model operation to maximize the operating rate of the equipment.

3. The peeling position is accurate, and there will be no accumulated error of traditional mechanical peeling, and poor peeling paint caused by the wear of the peeling knife. Completely avoid the risk of short circuit caused by peeling paint too long and deep wire package. There is no need to fine-adjust the paint stripping knife when changing the wire, only need to pull out the corresponding document from the program, which greatly saves the time of adjustment.

4. Visual laser welding, to achieve the precise positioning of the sheet end and enameled wire welding points, to ensure the welding effect, better than the traditional resistance welding strength.

5. High production efficiency, the output can reach 6Kpcs per hour.

6. Equipment program control operation, fast wire change speed. When responding to urgent orders from customers, it only takes one day from machine debugging to final product shipment, which has an incomparable advantage in responding quickly to customers and obtaining customer orders

System specification

Building 4, 88 Wubian Avenue, Wujiang District, Suzhou

Building 4, 88 Wubian Avenue, Wujiang District, Suzhou

Friendship link :