Mobile phone IO charging slot welding assembly welding automatic equipment

Price range: 900-1.2 million

Power: 150W

Warranty period: 2 years

Brand: Jinghai Laser

This device is mainly a mobile phone charging slot automatic assembly welding equipment. The whole line is divided into four stations, such as housing loading, ITO slot parts loading, laser welding automatic unloading, using rotary table automation, through the robot up and down fixture, direct and lower end process threading, improve production line efficiency.

Application description

This device is mainly a mobile phone charging slot automatic assembly welding equipment. The whole line is divided into four stations, such as housing loading, ITO slot parts loading, laser welding automatic unloading, using rotary table automation, through the robot up and down fixture, direct and lower end process threading, improve production line efficiency.

Laser application

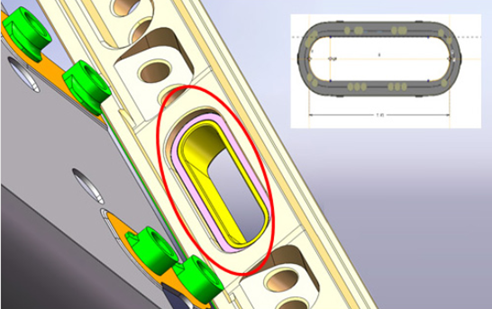

This device is mainly a mobile phone charging slot automatic assembly welding equipment.

IO stainless steel welding application: stainless steel material, drawing force more than 10KG; Welding type: seam welding; Solder joint arrangement: multi-spot welding, solder joint 0.4mm;

Core process: stainless steel welding

◆ Laser welding (spot welding process)

◆ High quality laser light source, independent research and development welding process

Functional characteristics

◆ Laser welding system has high stability and reliable performance;

◆ PLC networking, distributed control, automatic loading and unloading of manipulator, automatic clamping and positioning of workpiece, CCD detection, automatic reciprocating use of fixture, the whole welding process is fully automated;

◆ Linear motor transplanting on-line fixture, fast positioning;

◆ Modular design, single station can operate independently;

◆ CCD visual positioning system, precise and controllable welding position;

System specification

This device is mainly a mobile phone charging slot automatic assembly welding equipment. The whole line is divided into four stations, such as housing loading, ITO slot parts loading, laser welding automatic unloading, using rotary table automation, through the robot up and down fixture, direct and lower end process threading, improve production line efficiency.

Building 4, 88 Wubian Avenue, Wujiang District, Suzhou

Building 4, 88 Wubian Avenue, Wujiang District, Suzhou

Friendship link :