Mobile phone automatic bucket&slot&spring assembly and welding automatic equipment

Price range: 1.4-1.6 million

Power: 150W

Warranty period: 2 years

Brand: Jinghai Laser

This equipment is mainly for the automatic assembly and welding between the camera bracket and the mobile phone center plate housing. The whole line is divided into six stations, including housing feeding with camera bracket, solt metal sheet feeding and unloading, visual inspection, laser welding, visual inspection, automatic feeding, etc., using assembly line mode, direct and lower end process threading to improve production line efficiency.

Application description

This equipment is mainly for the automatic assembly and welding between the camera bracket and the mobile phone center plate housing. The whole line is divided into six stations, including housing feeding with camera bracket, solt metal sheet feeding and unloading, visual inspection, laser welding, visual inspection, automatic feeding, etc., using assembly line mode, direct and lower end process threading to improve production line efficiency.

Laser application

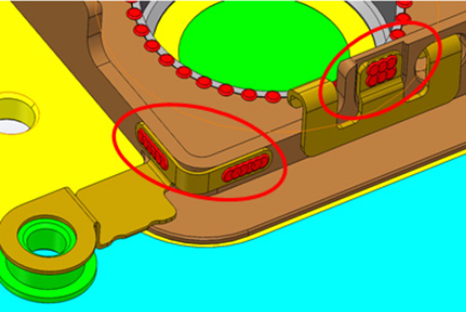

Automatic assembly welding between the camera bracket and the mobile phone center plate housing.

Core process:

◆ Laser welding (spot welding process)

◆ High quality laser light source, independent research and development welding process

Welding type: spot welding, stack welding.

Solder joint arrangement: multi-spot welding, the overlap rate of solder joints is more than 30%;

Functional characteristics

◆ PLC networking, distributed control of automatic loading and unloading, automatic clamping and positioning of workpiece, CCD detection, fixture automatic reciprocating cycle use, the whole welding process is fully automated;

◆ CCD visual positioning system, precise and controllable welding position

◆ Positioning accuracy ±0.05mm, repeated positioning accuracy ±0.03mm

◆ Pipeline structure, small equipment space;

◆ Automatic loading and unloading between each station;

◆ Modular design, suitable for workshop production line planning;

System specification

The whole line is divided into six stations, including housing feeding with camera bracket, solt metal sheet feeding and unloading, visual inspection, laser welding, visual inspection, automatic feeding, etc., using assembly line mode, direct and lower end process threading to improve production line efficiency.

Building 4, 88 Wubian Avenue, Wujiang District, Suzhou

Building 4, 88 Wubian Avenue, Wujiang District, Suzhou

Friendship link :