Wireless charging coil laser cleaning & cutting automation equipment

Price range: 700,000-900,000

Power: 120W

Warranty period: 2 years

Brand: Jinghai Laser

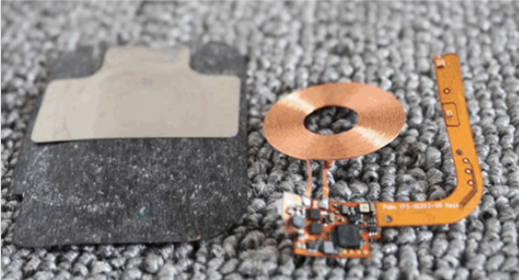

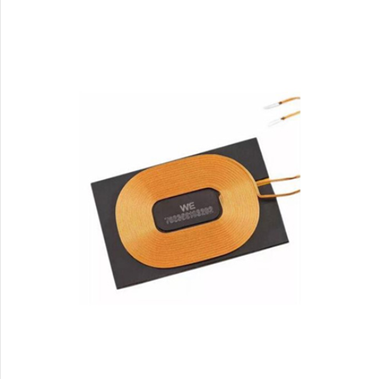

Consumer electronic products receiving wireless charging module, the internal coil after winding, need to laser cleaning paint coating on the positive and negative extremes, and then in accordance with a certain size of laser cutting, and finally welding with the PCB board, this equipment mainly completed the laser cleaning paint coating and laser cutting function, coil automatic loading and unloading.

Application description

Consumer electronic products receiving wireless charging module, the internal coil after winding, need to laser cleaning paint coating on the positive and negative extremes, and then in accordance with a certain size of laser cutting, and finally welding with the PCB board, this equipment mainly completed the laser cleaning paint coating and laser cutting function, coil automatic loading and unloading.

Laser application

After winding the internal coil, it is necessary to carry out laser cleaning coating on the positive and negative extremes, and then laser cutting in accordance with a certain size, and finally welding with the PCB board. This equipment mainly completes the laser cleaning coating and laser cutting function, and the coil automatic loading and unloading. Core process:

◆ Laser cleaning (coating removal)

◆ Laser cutting

Functional characteristics

◆ Laser welding system has high stability and reliable performance;

◆ PLC networking, distributed control of automatic loading and unloading, automatic clamping and positioning of workpiece, CCD detection, fixture automatic reciprocating cycle use, the whole welding process is fully automated;

◆ Linear motor transplanting on-line fixture, fast positioning;

◆ Modular design, single station can operate independently;

◆ CCD visual positioning system, precise and controllable welding position;

System specification

Consumer electronic products receiving wireless charging module, the internal coil after winding, need to laser cleaning paint coating on the positive and negative extremes, and then in accordance with a certain size of laser cutting, and finally welding with the PCB board, this equipment mainly completed the laser cleaning paint coating and laser cutting function, coil automatic loading and unloading.

Building 4, 88 Wubian Avenue, Wujiang District, Suzhou

Building 4, 88 Wubian Avenue, Wujiang District, Suzhou

Friendship link :