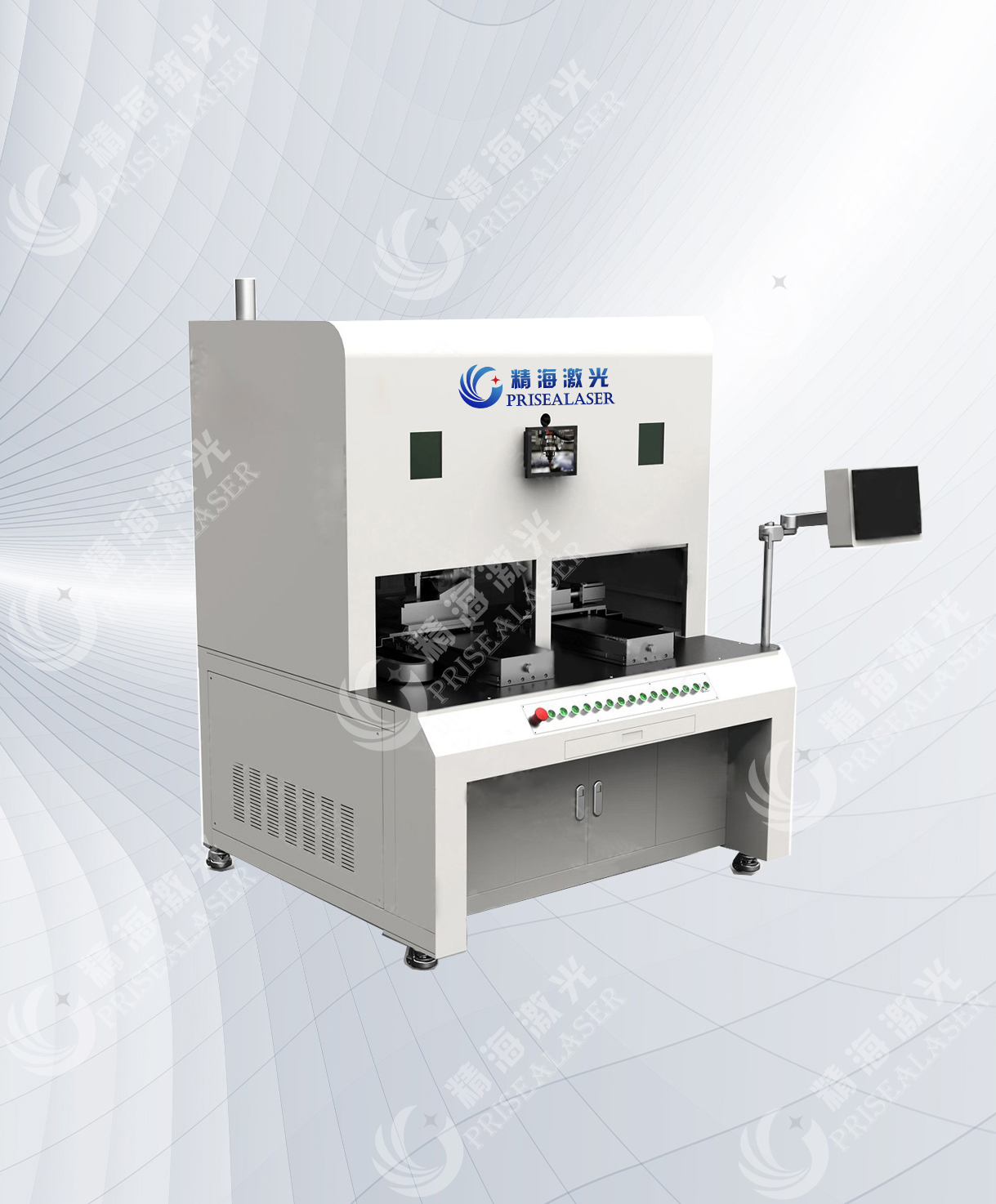

Automotive instrument panel laser plastic welding workstation

Price range: 300,000-500,000

Power: 120W

Warranty period: 2 years

Brand: Jinghai Laser

The laser plastic welding workstation is used for the sealing and welding of the transparent plastic cover plate of the automobile instrument panel. The use of laser plastic welding instead of the original ultrasonic welding can effectively eliminate the problem of product yield reduction caused by mechanical wear.

Application description

Laser application

The plastic laser welding process has the following advantages in the instrument panel welding:

1. No vibration during welding. Plastic laser welding is a non-contact welding method, the upper and lower workpiece is stationary after the clamp, and there is no relative displacement during the welding process. Therefore, the plastic laser welding process is particularly easy to protect the exterior surface of the product.

2, almost no overflow, welding line appearance is beautiful. The welding line formed by plastic laser welding is very beautiful and can be directly used as the appearance surface. In the process of laser welding, it is not like vibration and friction welding, because a large number of welding joints collapse, resulting in a lot of overflow in the welding area, and the welding line is very ugly. This is also the main reason for the use of laser welding in automotive interior and exterior trim parts.

Functional characteristics

The plastic laser welding process has the following advantages in the instrument panel welding:

1. No vibration during welding. Plastic laser welding is a non-contact welding method, the upper and lower workpiece is stationary after the clamp, and there is no relative displacement during the welding process. Therefore, the plastic laser welding process is particularly easy to protect the exterior surface of the product.

2, almost no overflow, welding line appearance is beautiful. The welding line formed by plastic laser welding is very beautiful and can be directly used as the appearance surface. In the process of laser welding, it is not like vibration and friction welding, because a large number of welding joints collapse, resulting in a lot of overflow in the welding area, and the welding line is very ugly. This is also the main reason for the use of laser welding in automotive interior and exterior trim parts.

System specification

The welding of automobile instrument panel and other similar products adopts the working mode of manual loading and unloading, Y-axis feeding, and four-axis linkage of welding head.

◆ With CD monitoring function, real-time monitoring of welding process

◆ Can be equipped with a vision system to achieve pre-welding positioning and post-welding detection functions

◆ The copying fixture makes the product positioning reliable, and the fixed upper pressure device has high positioning accuracy

◆ Multi-dimensional linkage welding head can achieve 3D welding effect

◆ Welding of various instrument products can be realized by replacing different fixtures

Building 4, 88 Wubian Avenue, Wujiang District, Suzhou

Building 4, 88 Wubian Avenue, Wujiang District, Suzhou

Friendship link :