High speed laser welding line system for module connectors

Price range: 1.7-2 million

Power: 4000W

Warranty period: 2 years

Brand: Jinghai Laser

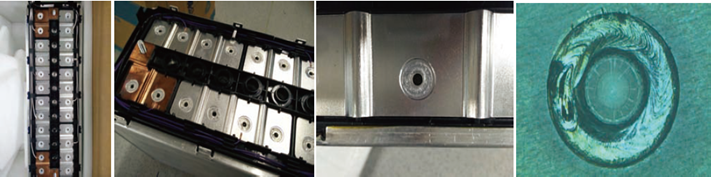

The equipment is used for high-speed automatic welding of Busbar and pole. The equipment has automatic busbar pressing and positioning, CCD welding seam addressing and focal length automatic correction Automatic feedback of welding power, automatic storage of welding parameters, upload the data to the customer MES system and other functions.

Application description

The equipment is used for high-speed automatic welding of Busbar and pole. The equipment has the functions of automatic busbar pressing and positioning, CCD welding seam addressing, automatic focal length correction, automatic welding power feedback, automatic storage of welding parameters, and upload the data to the customer MES system. The assembly line flow fixture is used, and there are loading position (lift), pre-welding insulation test position (customer equipment), front rotating table, pre-welding photo positioning, human tooling wire harness isolation board station, Busbar laser welding station and post-welding slag cleaning station, EOL test station (customer equipment), bonding station (customer equipment reserved station), Rear rotating table, four manual test position, cutting level (lift), fixture automatic reflux system. The system adopts IPG6000W laser welding machine, which automatically takes photos, locates the weld position and defines the MARK by distance, and the robot drives the galvanometer to carry out automatic high-speed laser welding on the weld position according to the photo data, and automatically cleans the welding slag after welding, and is equipped with the fixture automatic assembly line system, fixture and the first fixture. Welding position automatic protection gas protection and double bottle protection gas automatic switching, automatic gas knife. The module information of manual installation of wire harness partition station is directly written into the industrial computer MES system provided by the customer. The system automatically generates all data and saves it locally and uploads it to the customer MES system.

Laser application

Functional characteristics

Loading position, clamp the module on the fixture, read the two-dimensional code of the module, and then write the RFID to the fixture, so that the rear station can use the camera position before welding, use the distance value to judge whether the module has been placed flat on the fixture, take photos of the pole coordinates and MARK points to establish a coordinate system, and the calculation result is given to the welding station, two stations, At the same time, one station is welding with laser galvanometer, and the other station is dusting, discharging, feeding and positioning after welding to improve efficiency, and the two stations are carried out alternately.

System specification

Using the pipeline flow fixture, there are loading position (lift), pre-welding insulation test position (customer equipment), front rotating table, pre-welding photo positioning, human tooling wire harness isolation board station, Busbar laser welding position and post-welding welding slag cleaning, EOL test station (Customer equipment), bonding station (customer equipment reserved station), after rotation table, four manual test position, cutting position (lift), fixture automatic return system. The system adopts IPG6000W laser welding machine, which automatically takes photos, locates the weld position and defines the MARK by distance, and the robot drives the galvanometer to carry out automatic high-speed laser welding on the weld position according to the photo data, and automatically cleans the welding slag after welding, and is equipped with the fixture automatic assembly line system, fixture and the first fixture. Welding position automatic protection gas protection and double bottle protection gas automatic switching, automatic gas knife. The module information of manual installation of wire harness partition station is directly written into the industrial computer MES system provided by the customer. The system automatically generates all data and saves it locally and uploads it to the customer MES system.

Building 4, 88 Wubian Avenue, Wujiang District, Suzhou

Building 4, 88 Wubian Avenue, Wujiang District, Suzhou

Friendship link :