Square cell pole (soft connection) laser welding equipment

Price range: determined by the scheme

Power: 4000W

Warranty period: 2 years

Brand: Jinghai Laser

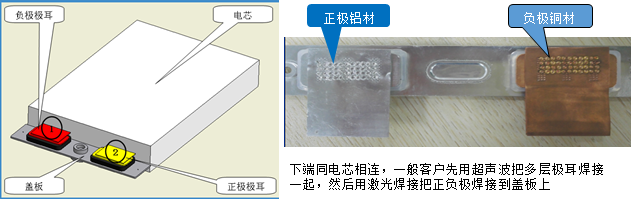

Square battery pole ear welding generally refers to the welding of soft connections (battery internal pole ear, rather than referring to the battery external pole to nickel/connection sheet), this connection sheet is not only connected with the pole, but also welded with the battery pole, which belongs to the middle transition section of the square battery inside, but also needs to be bent, the positive electrode of the welding material is generally aluminum/aluminum foil. Negative electrode nickel plated copper foil.

Application description

Square battery pole ear welding generally refers to the welding of soft connections (battery internal pole ear, rather than referring to the battery external pole to nickel/connection sheet), this connection sheet is not only connected with the pole, but also welded with the battery pole, which belongs to the middle transition section of the square battery inside, but also needs to be bent, the positive electrode of the welding material is generally aluminum/aluminum foil. Negative electrode nickel plated copper foil. In order to reduce the internal resistance and improve the battery performance, laser welding needs to pay attention to avoid virtual welding, or metal debris, so as not to cause high internal resistance of the battery

, affecting the charging and discharging temperature rise, affecting the use of the battery quality and safety and effective service life. Therefore, it is particularly important to have a set of laser welding machines of good quality for welding square battery electrodes.

Laser application

Functional characteristics

SCANLAB galvanometer welding, high-speed laser scanning, high efficiency, high production, low cost;

German IPG fiber laser, modular plug and play design, maintenance-free operation; LDD real-time quality measurement options for welding applications;

Adjustable ring beam laser option, easy to handle automated laser welding;

The top laser coding technology, and the dimension code clarity above B level, to ensure that product information can be traced;

Coaxial visual monitoring, air knife, smoke exhaust device, bar code scanner;

Fully enclosed design, with efficient smoke dust removal, efficient suppression of dust hazards.

System specification

1, manual loading and unloading, can achieve double station production.

2, with the help of clamping pole ear, you can batch pressing at the same time.

3, laser scanning welding in large format.

4, the welding path can be ". Z" Font, can better reduce the internal resistance, strengthen the solid strength of welding.

5, the operation is simple, that is, learn to get started.

Automatic welding line:

1, automatic loading and unloading.

2. The connection piece is pressed and positioned to detect itself and correct the position deviation.

3. Automatic detection of welding effect to avoid virtual welding.

4. Automatically bend the connection piece.

5, automatic cutting.

Whether it is a stand-alone version or an automatic production line, the equipment has a tight structure and smooth operation, and different welding production lines can be customized for different users.

Building 4, 88 Wubian Avenue, Wujiang District, Suzhou

Building 4, 88 Wubian Avenue, Wujiang District, Suzhou

Friendship link :