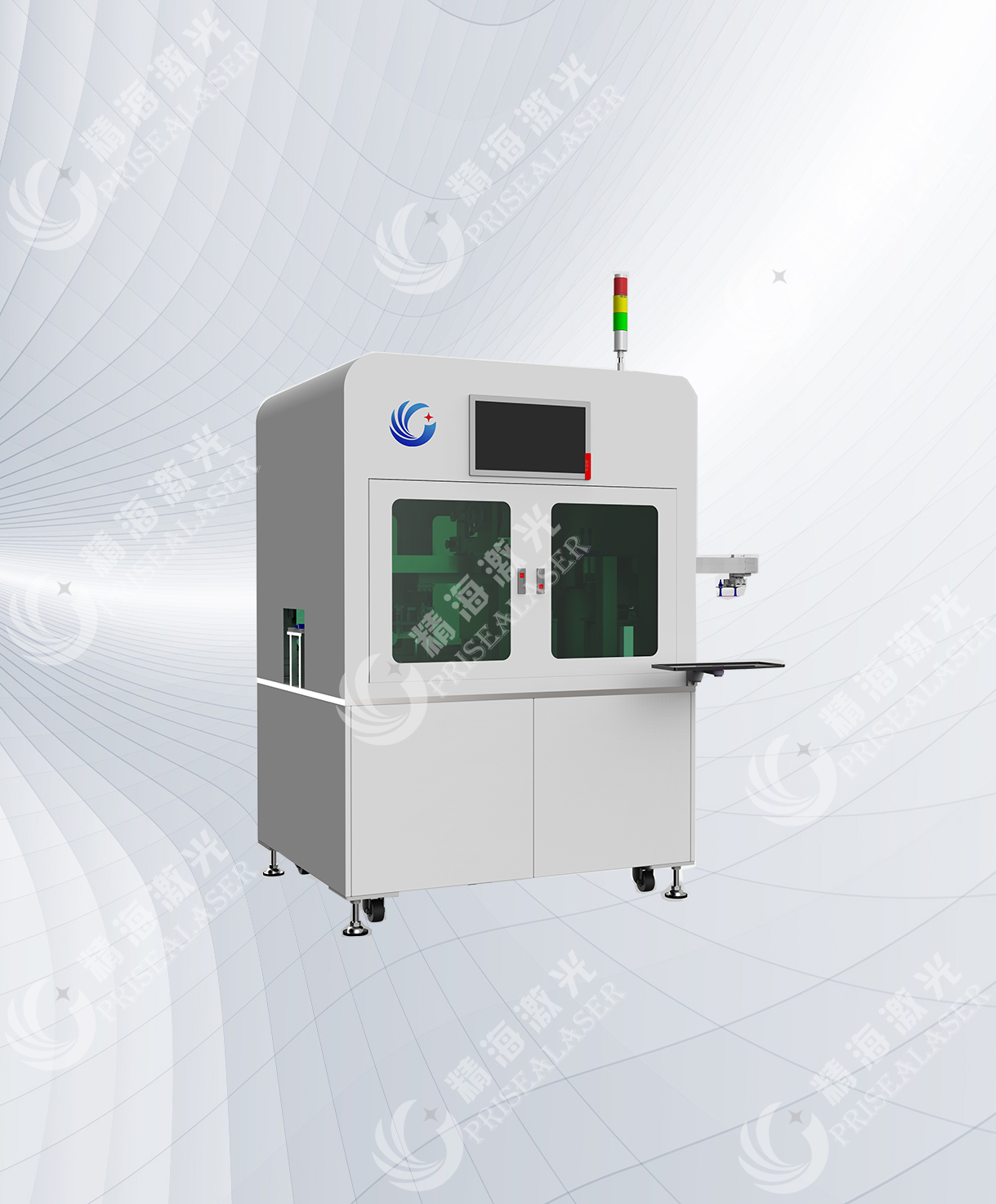

Mobile phone camera VCM laser welding machine

Price range: 300,000-500,000

Power: 150W

Warranty period: 2 years

Brand: Jinghai Laser

Mobile phone camera VCM precision laser welding machine is a high-performance precision laser welding product launched by Jinghai Laser for the subdivision of mobile phone parts. Using fiber laser source, high stability galvanometer system, high-precision CCD positioning system and power monitoring system, it is specially customized for VCM precision parts and has ultra-high cost performance. Equipment adopts double station table, welding fixture...

Application description

Mobile phone camera VCM precision laser welding machine is a high-performance precision laser welding product launched by Jinghai Laser for the subdivision of mobile phone parts. Using fiber laser source, high stability galvanometer system, high-precision CCD positioning system and power monitoring system, it is specially customized for VCM precision parts and has ultra-high cost performance.

The equipment adopts double station workbench, the welding fixture adopts one mode and multiple holes, and the welding process is programmable control, with high production efficiency and high cost performance of the equipment.

VCM Motor, VCM(Voice Coil

Motor), Chinese name voice coil motor. Originally used to produce vibrating sound from loudspeakers, the imaging module is now used to push the lens to produce autofocus. The main principle is that the coil and the lens barrel are fixed together, and the stretching position of the spring plate is controlled by changing the DC current of the coil in the motor, so that the lens barrel moves forward and backward. Simply put, when the phone's camera focuses on subjects at different distances, the gadget will help the lens achieve automatic focus function.

The VCM structure of different manufacturers is slightly different, roughly divided into the following major components:

Common VCM structures

Shield Case: shell

I want to Frame my frame.

F.spater: Front gasket for insulation

F. Spring: Front spring, used to carry the carrier and balance the torque.

Yoke: Used to fix other components,

Magnet: A magnet that generates a permanent magnetic field

Coil: A coil that is powered on to generate a driving torque

Carrier: The carrier that carries lens B.

Spacer: Rear gasket for insulation B.

Spring: Rear spring, used to carry the carrier and balance the torque

Base: A base used to secure components.

Laser application

Functional characteristics

There are so many parts the size of the nail, you can imagine how high the precision requirements of VCM processing, in such a precision processing process, the advantages of laser welding can be fully played.

● Laser welding weld quality is high;

● Laser welding speed, high production efficiency, simple control, easy to automate;

● Because laser processing is non-contact, residue problems and electrostatic phenomena during processing can be avoided.

System specification

Building 4, 88 Wubian Avenue, Wujiang District, Suzhou

Building 4, 88 Wubian Avenue, Wujiang District, Suzhou

Friendship link :