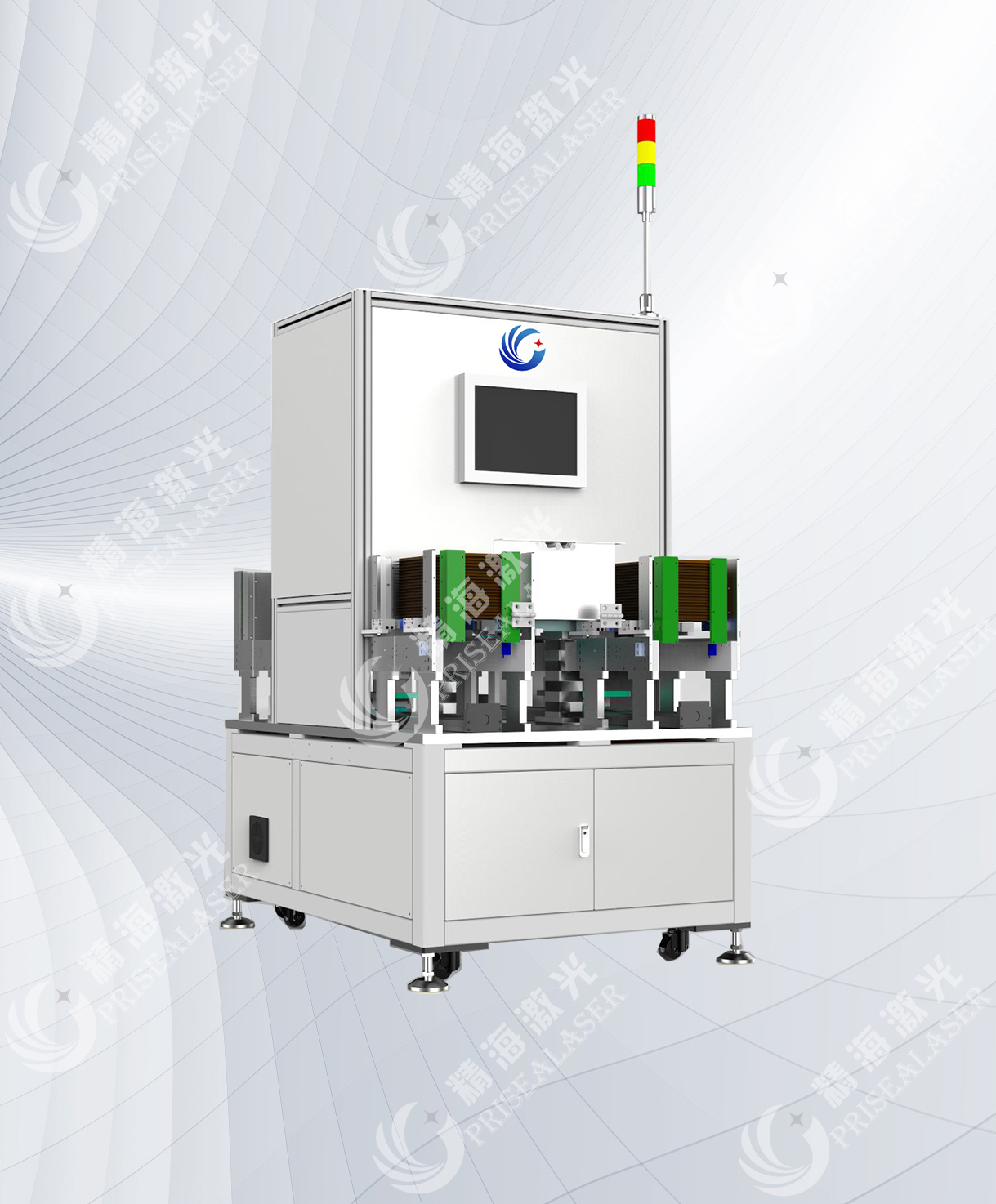

Mobile vibration motor laser welding machine

Price range: 300,000-500,000

Power: 150W

Warranty period: 2 years

Brand: Jinghai Laser

Metal motor laser welding machine basically no consumables, significantly reduce downtime auxiliary time, high production efficiency; And because the focused spot is very small, the weld can be positioned with high precision, and the beam is easy to transmit and control, so it can be welded at a distance or some parts and micro-parts that are difficult to access.

Application description

It is the transliteration of English motor, that is, electric motor and engine. The working principle is to drive the starter rotor to rotate through electromagnetic induction, and the pinion on the rotor drives the engine flywheel to rotate. The micro vibration motor mainly used in mobile phones is a DC brush motor, the motor shaft has a eccentric, when the motor rotates, the eccentric center particle is not in the motor center, making the motor in a constant state of loss of balance, due to inertia caused vibration. Laser welding is a new type of welding method, this welding method can create more than the strength of raw materials welding joints, metal motor laser welding machine basically no consumables, significantly reduce the downtime auxiliary time, high production efficiency; And because the focused spot is very small, the weld can be positioned with high precision, and the beam is easy to transmit and control, so it can be welded at a distance or some parts and micro-parts that are difficult to access.

Laser application

Covar alloy seam welding

Application Description: 0.2mm- stainless steel frame, solder joint within 0.5mm, drawing force more than 10KG;

Welding type: spot welding, seam welding/stack welding.

Solder joint arrangement: uniform distribution or array distribution;

Functional characteristics

• Imported pulse laser generator, stable performance

• Imported high-speed galvanometer, high processing accuracy, marking speed, stable performance

• Humanized software interface, easy to operate and learn, strong editing function

• Optional visual positioning system to guide laser welding, can improve product consistency;

• Better processing efficiency combined with automation

• Laser welding module no consumables, maintenance-free;

System specification

Building 4, 88 Wubian Avenue, Wujiang District, Suzhou

Building 4, 88 Wubian Avenue, Wujiang District, Suzhou

Friendship link :